Burracoppin Iron Project

MINING, BIOMASSING and SMELTING

to produce

GREEN HIGH PURITY PIG IRON.

Reedy Lagoon is pursuing a plan to produce and sell Green High Purity Pig Iron ("Green HPPI") by:

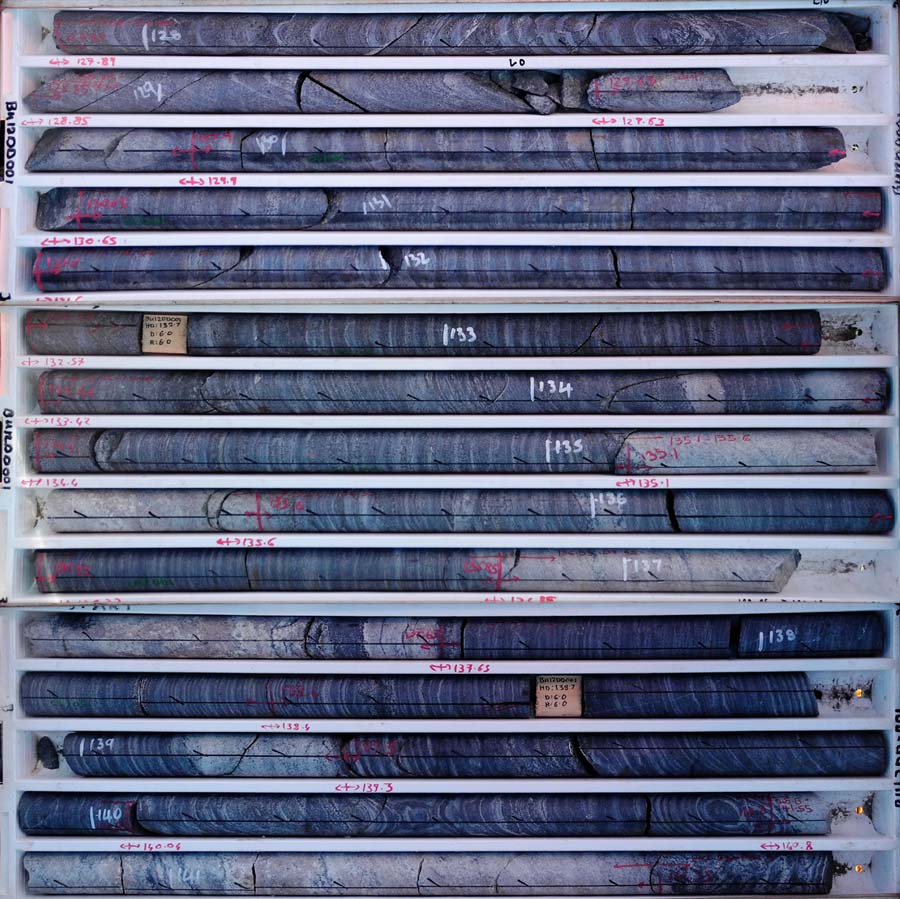

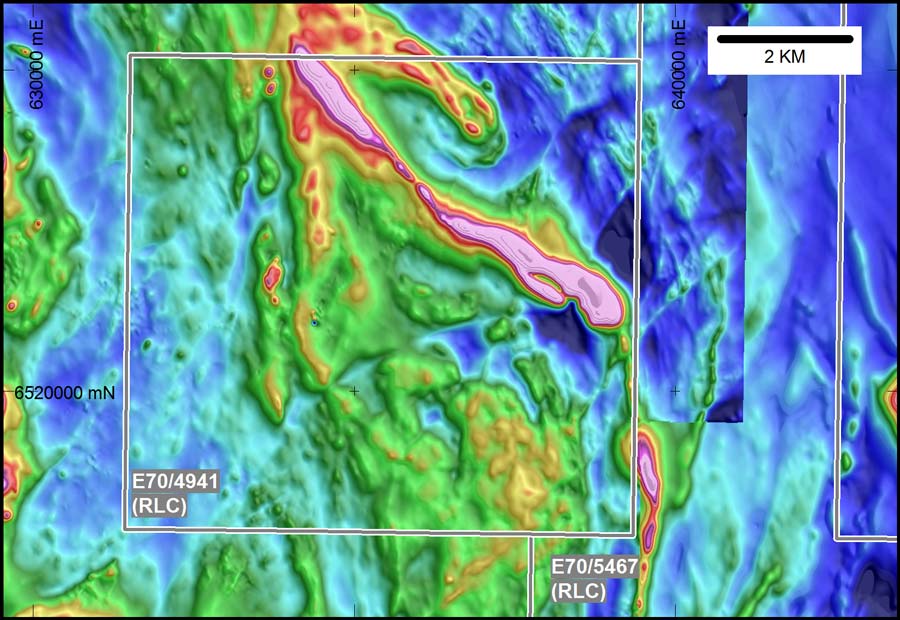

- Mining mineral magnetite from the Burracoppin deposit to produce iron concentrate

- Growing or otherwise acquiring biomass for processing to produce biochar

- Smelting the iron concentrate with the biochar using HIsmelt technology to produce Green HPPI

- Selling Green HPPI to steel makers in Australia, North America, Europe, UK and Asia.

Operating scenarios for processing Burracoppin magnetite to produce Green High Purity Pig Iron using HIsmelt technology and biochar from locally grown biomass were investigated in a study undertaken for the Company by Dinsdale Consultants (refer to ASX release 19/03/2021). The scenarios consider an initial 1 Mtpa rate of Pig Iron production which would require approximately 1.6 Mtpa Burracoppin iron concentrate and extends research previously conducted which identified that the HIsmelt technology could use biochar to smelt the coarse grained Burracoppin magnetite concentrate to produce HPPI with zero net emissions of CO2 (refer to ASX release 20/08/2020).

Project economics are enhanced by using Burracoppin magnetite concentrate for feed to a HIsmelt smelter to produce High Purity Pig Iron for sale into the steel making market. The alternative of selling magnetite concentrate (an iron ore) into the iron ore market carries greater risk because of the concentration of the iron ore market. The iron ore market is dominated by a single buyer, China, with over 80% of the seaborne trade. This market dominance exposes the market to large price swings as is evidenced by price movements over the last two years. In contrast, the market for solid pig iron is more diverse being spread across USA (60%), EU (30%) and others (10%) creating greater price stability (refer to ASX release 20/08/2020).

The steps required to achieve annual production of 1Mtpa Green High Purity Pig Iron include establishing the following:

- Mining - Burracoppin Magnetite

- Biomassing for Carbon Cycling

- Smelting - HIsmelt

- Product - High Purity Pig Iron

For detail and updates, refer to the latest Quarterly Activities reports and other ASX announcements.